UPSC CURRENT AFFAIRS – 18th May 2025

Understanding Failure Modes in Solid-State Lithium-Ion Batteries

Why in News?

A new study published in Science reveals that dendritic failure in solid-state Li-ion batteries (SSBs) is linked to mechanical fatigue, a principle long known in material science. This finding is significant for improving the longevity, safety, and reliability of next-generation batteries.

Key Highlights

- Solid-state batteries (SSBs) use a solid electrolyte instead of a liquid, offering higher energy density and safety.

- Researchers observed that microscopic lithium dendrites, resembling plant roots, grow into the solid electrolyte during repeated charging/discharging cycles.

- The failure arises not from high current but from mechanical fatigue due to cyclic stress on the lithium anode.

- Operando scanning electron microscopy helped visualize dendrite formation in real-time.

- The battery short-circuited at the 145th cycle due to void formation and electrolyte fracture—even under minimal current.

- Implications include more sophisticated battery failure models and better design for durable energy storage systems.

What Are Solid-State Li-ion Batteries?

- SSBs use ceramic or solid polymer electrolytes in place of flammable liquid electrolytes.

- Used in pacemakers, smartwatches, and under development for electric vehicles (EVs) and grid storage.

- Advantages:

- Safer (non-flammable).

- Lighter and more energy dense.

- Lower risk of leakage or thermal runaway.

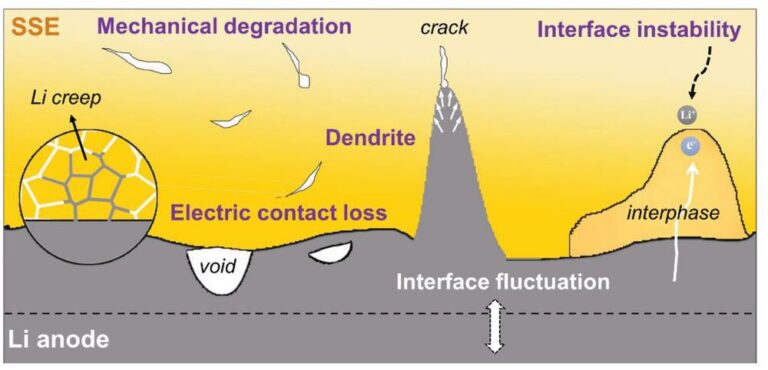

Key Failure Mechanism: Dendritic Growth

- Lithium ions get deposited unevenly at the anode during charging.

- Filament-like dendrites grow and penetrate the solid electrolyte.

- Result: Internal short-circuit, leading to rapid failure of the cell.

- Fatigue caused by repeated cycling even at low currents causes structural weaknesses.

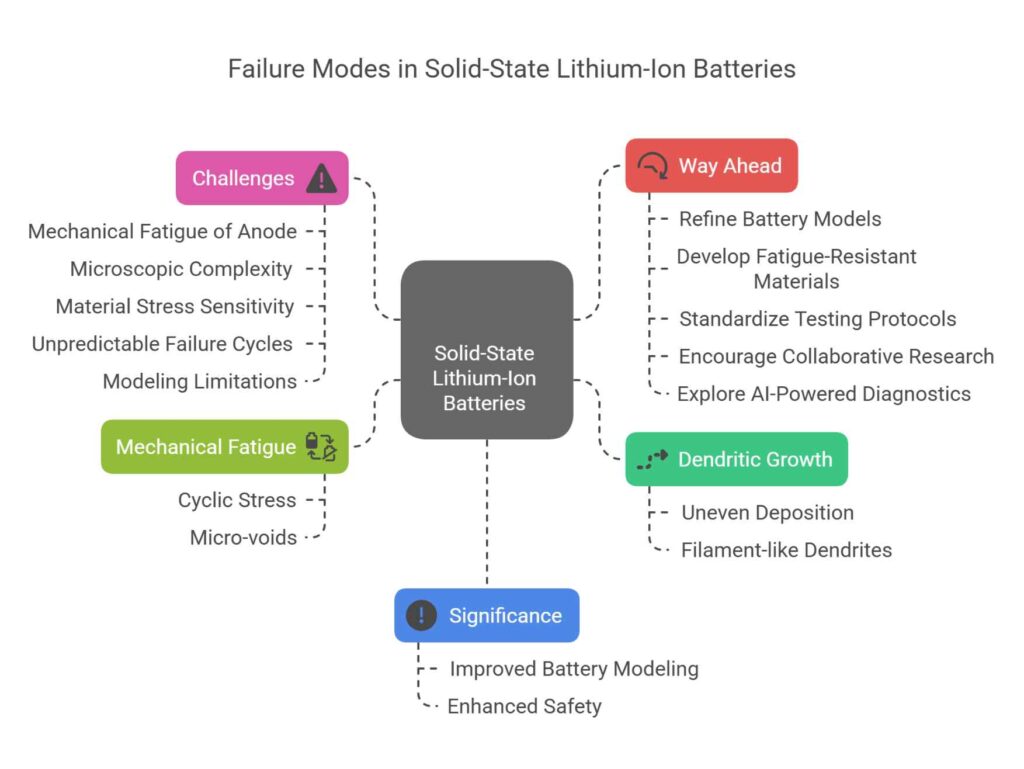

Challenges Identified

- Mechanical Fatigue of Anode:

- Analogous to bending a wire until it breaks.

- Lithium stripping and plating cycles cause micro-voids, slip bands, and cracks.

- Microscopic Complexity:

- Dendrites are invisible to the naked eye, making early detection difficult.

- Operando microscopy is needed to observe real-time interface evolution.

- Material Stress Sensitivity:

- Solid electrolytes are brittle and crack under volume changes or stress.

- No standard method yet to counter lithium’s stress-strain behavior under varied temperatures.

- Unpredictable Failure Cycles:

- Short-circuiting can occur without warning even under safe current limits.

- Modeling Limitations:

- Existing battery degradation models do not fully account for mechanical fatigue effects.

- Lack of integrated electro-chemo-mechanical models limits predictive capability.

Significance

- A breakthrough in understanding why SSBs fail even at low power settings.

- Will guide next-generation battery modeling, design, and predictive diagnostics.

- Can boost the safety and adoption of SSBs in sectors like EVs and aerospace.

India-Specific Impact

- Boost to EV and Energy Storage R&D

- India is pushing battery innovation under FAME-II, PLI Scheme for Advanced Chemistry Cell Batteries, and National Electric Mobility Mission Plan.

- Indian institutions like IISc Bengaluru and IITs are actively involved in SSB research.

- The findings can help Indian startups and research centres develop more durable batteries, reducing EV recall and performance issues.

- Local Manufacturing and Make-in-India Goals

- With plans for gigafactories, understanding failure mechanisms is critical for local cell assembly.

- Can reduce dependency on imported battery designs that may not suit India’s temperature and usage conditions.

- Improved Battery Standards and Certification

- BIS and other regulatory bodies can revise battery certification norms based on fatigue-informed models.

- Critical for applications in high-risk environments like defense and aviation.

- Grid-Scale Renewable Integration

- India’s solar and wind sectors need reliable, long-life storage solutions.

- Fatigue-resistant SSBs can enable off-grid and hybrid mini-grid projects in rural and remote regions.

Way Ahead

- Refine battery models to incorporate lithium’s fatigue behavior under cyclic stress and temperature variation.

- Develop fatigue-resistant electrode materials and flexible electrolytes.

- Standardize microscopy-based testing protocols during SSB design.

- Encourage collaborative research in electro-mechanical modeling of batteries.

- Explore AI-powered diagnostics for early detection of dendritic growth and fatigue damage.

Conclusion

The discovery linking dendritic failure in SSBs to mechanical fatigue marks a paradigm shift in battery research. While manufacturing changes may remain limited, this insight is crucial for building longer-lasting, safer, and more efficient solid-state batteries—critical for India’s push toward EV adoption, renewable storage, and energy security.

3rd UN conference on landlocked countries

UPSC CURRENT AFFAIRS – 08th August 2025 Home / 3rd UN conference on landlocked countries Why in News? At the

Issue of soapstone mining in Uttarakhand’s Bageshwar

UPSC CURRENT AFFAIRS – 08th August 2025 Home / Issue of soapstone mining in Uttarakhand’s Bageshwar Why in News? Unregulated

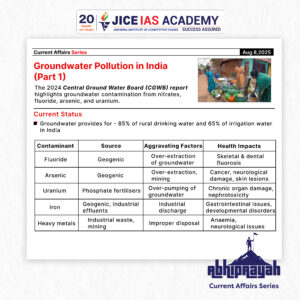

Groundwater Pollution in India – A Silent Public Health Emergency

UPSC CURRENT AFFAIRS – 08th August 2025 Home / Groundwater Pollution in India – A Silent Public Health Emergency Why

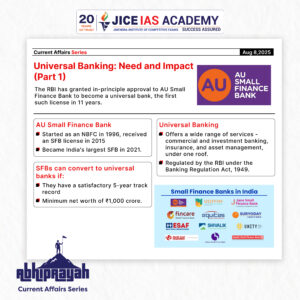

Universal banking- need and impact

UPSC CURRENT AFFAIRS – 08th August 2025 Home / Universal banking- need and impact Why in News? The Reserve Bank

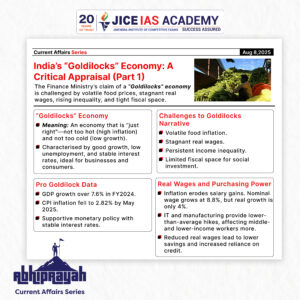

India’s “Goldilocks” Economy: A Critical Appraisal

UPSC CURRENT AFFAIRS – 08th August 2025 Home / India’s “Goldilocks” Economy: A Critical Appraisal Why in News? The Finance

U.S.-India Trade Dispute: Trump’s 50% Tariffs and India’s Oil Imports from Russia

UPSC CURRENT AFFAIRS – 07th August 2025 Home / U.S.-India Trade Dispute: Trump’s 50% Tariffs and India’s Oil Imports from

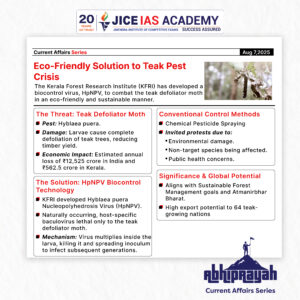

Eco-Friendly Solution to Teak Pest Crisis: KFRI’s HpNPV Technology

UPSC CURRENT AFFAIRS – 07th August 2025 Home / Eco-Friendly Solution to Teak Pest Crisis: KFRI’s HpNPV Technology Why in

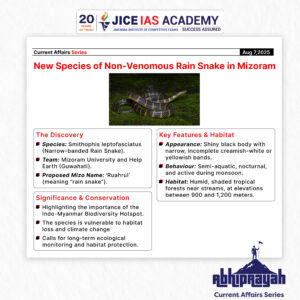

New Species of Non-Venomous Rain Snake Discovered in Mizoram

UPSC CURRENT AFFAIRS – 07th August 2025 Home / New Species of Non-Venomous Rain Snake Discovered in Mizoram Why in